Building the Double Disc Sander

Building The Double Disc Sander

I needed a disc sander for shaping and sanding parts and did not want to mess around with changing grit on and off, so I decided to make a double one with 2 discs, driven by 1 motor.

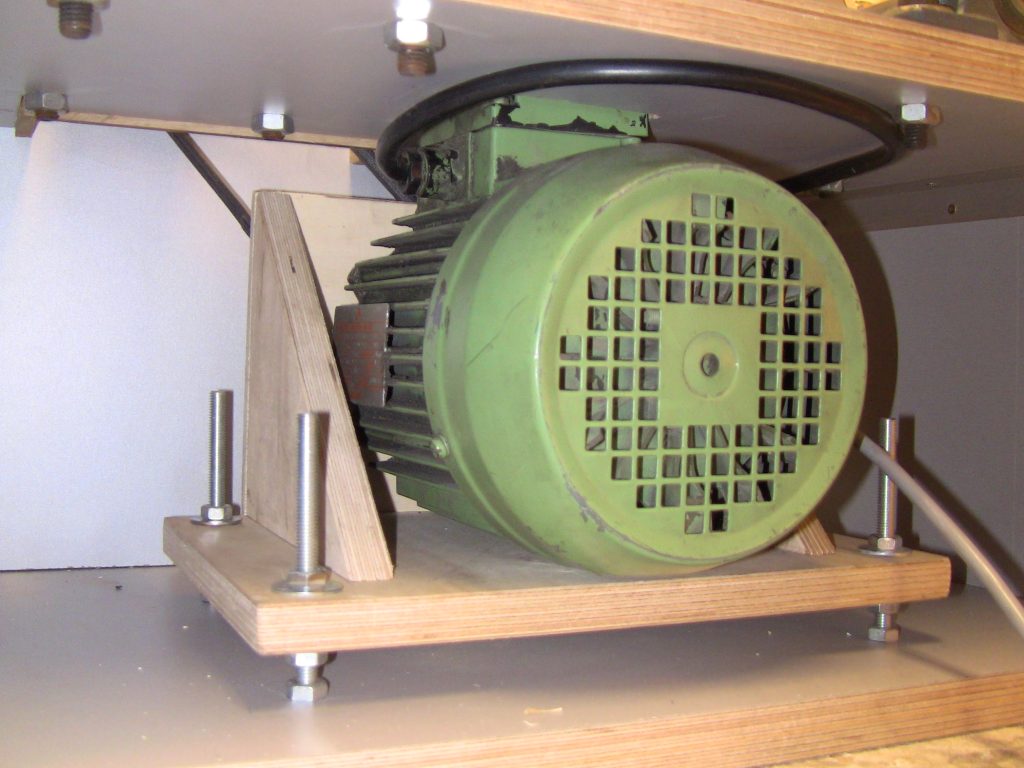

I started with the salvaged motor which is a 550w 3 phase motor. I do not have 3 phase power in my home, so it has to be run on a capacitor.

This of course reduces the power and torque, but it has turned out to be hard to stall it anyway.

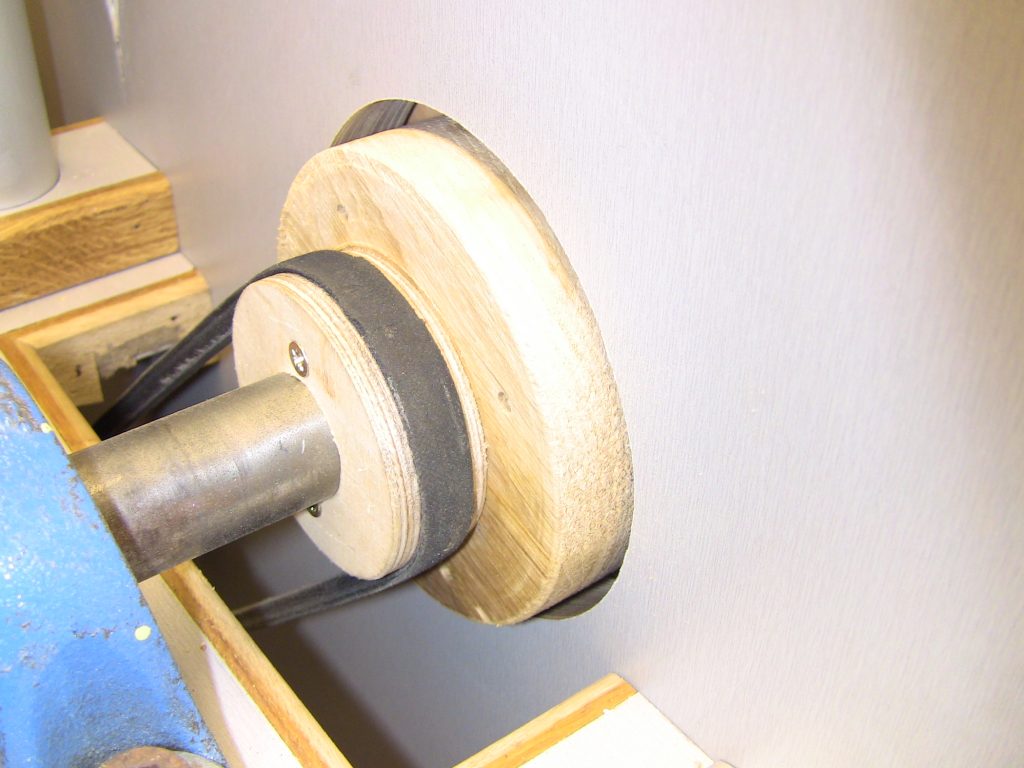

Starting out with making the pulleys from plywood, and using some v belt i had laying in a drawer to determin the overall size of the sander.

Motor mount is made from 18mm and 9mm baltic birch plywood

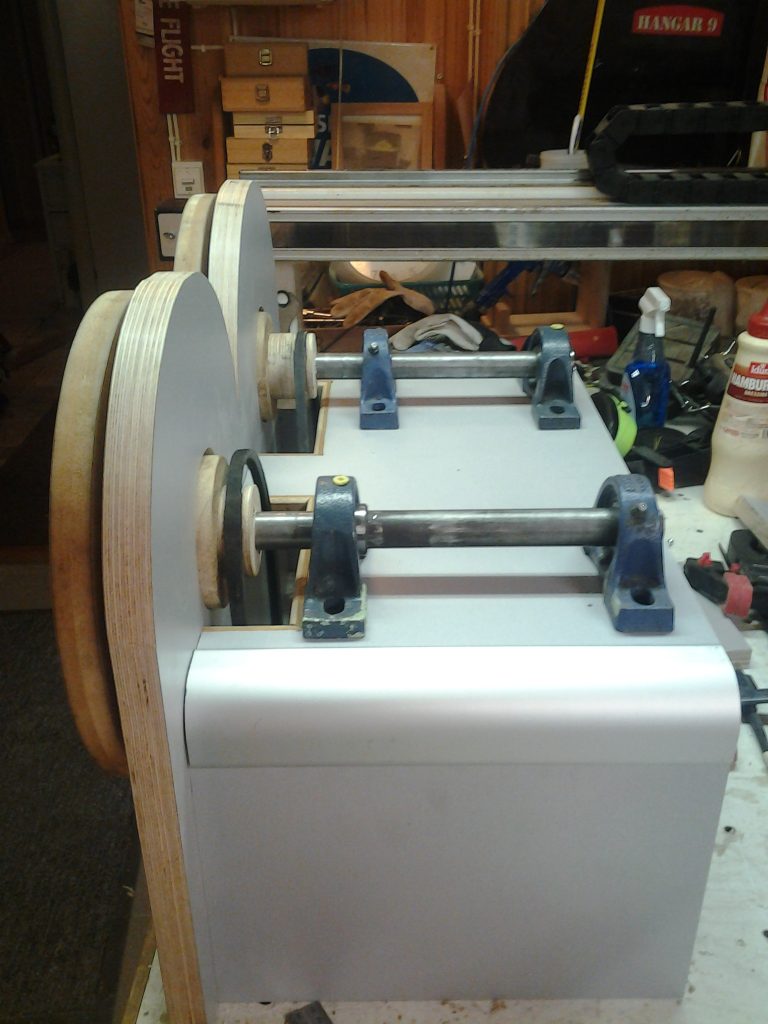

After making the attachment plates from oak, and mounting the “faceplates” and pulleys to the shafts the pillow block bearings are mounted.

The attachmentplates made from oak, are trued after mounting it to the shaft, in a metal lathe. this made attaching the 12″ “faceplates” a breeze. It did not need any further ballancing

The controlbox for the on/off switch are just miterd 9mm ply

Parts beeing painted and ready for assembly

For better dust collection there is a strip of plywood mounted to help guide the sawdust to the dustport

Tilting table painted and installed in 90 degree position

And at 45 degree position

A closeup of the adjustment for the angle of the table

The motormount is mounted on 4 threaded rods, to be able to adjust tension on v-belts.

A closeup of the wooden pulleys

Conclusion:

I think if I were to build it again I would have settled for a 1 disc sander. these machines are mainly used for shaping, and the right side with the 120 grit is rarely used.

Here is a video of the sander in action